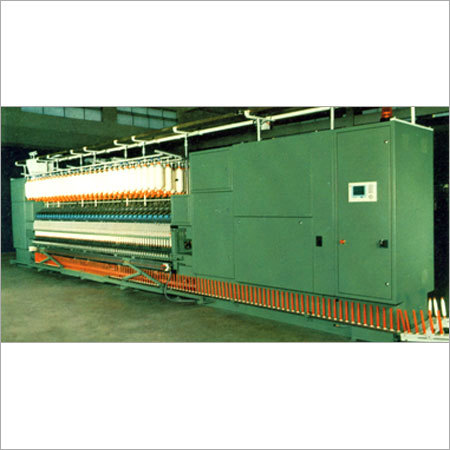

Ring Frame Machine

Price 1 INR/ Unit

MOQ : 1 Unit

Ring Frame Machine Specification

- Frequency

- 50/60 Hz

- Hook

- Available

- Product Type

- Ring Frame Machine

- Material

- Mild Steel

- Machinery Type

- Spinning Machinery

- Capacity

- High Production

- Dimension (L*W*H)

- Customized

- Color

- Blue & White

- Application

- Cotton, Synthetic, and Blended Yarn

- Spindle Speed

- Up to 25,000 RPM

- Frame Structure

- Robust & Stable

- Drive Type

- Individual or Central

- Energy Consumption

- Optimized for Efficiency

- Noise Level

- Low

- Draft Range

- Up to 80

- No. of Spindles

- Up to 1200

- Automation Grade

- Automatic

- Lubrication System

- Centralized/Automatic

Ring Frame Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Week

About Ring Frame Machine

Being a trustworthy organization in this domain, we are engaged in offering the best quality Ring Frame Machine. This technology is widely used for spinning and processing of yarns for textile industry. The provided machine is manufactured with an aid of advanced technology in accordance with international quality standards. Moreover, this Ring Frame Machine can be purchased from us at market leading price.

Key points:

- Low power consumption

- User friendly

- Touch screen display

- Low maintenance

Cutting-Edge Automation for Consistent Yarn Quality

This ring frame machine features advanced automatic controls and spindle speeds up to 25,000 RPM. Such technology ensures uniform yarn production with minimal manual intervention and reduces the chance of human error. The automatic lubrication and optimized energy usage contribute to operational efficiency, making it a preferred choice for modern spinning mills dealing with cotton, synthetic, or blended fibers.

Engineered for Stability and High Productivity

A robust, mild steel frame structure and the option of up to 1,200 spindles guarantee stability and high output rates. Whether you operate with individual or central drives, this machine supports bulk production requirements. Centralized lubrication and low noise emissions ensure a safe and comfortable environment for operators, while customizable dimensions fit diverse factory layouts.

FAQs of Ring Frame Machine:

Q: How does the automatic ring frame machine enhance yarn production efficiency?

A: The machine integrates automated controls and optimized energy management, significantly increasing productivity. Automatic spindle speed adjustment up to 25,000 RPM and efficient lubrication mean less downtime and consistent, high-quality yarn output.Q: What materials can be processed using this ring frame machine?

A: This machine is designed for versatility, processing cotton, synthetic, and blended yarns with ease. Its robust structure and fine-tuned mechanics cater to a wide range of fiber types common in the textile industry.Q: When is it advisable to choose a centralized versus individual drive system?

A: Centralized drive systems are ideal for large-scale operations requiring uniform power distribution and simplified maintenance. Individual drives can be selected when flexibility or specific speed control for each spindle section is necessary.Q: Where can installation and after-sales services for this machine be accessed?

A: Installation and support are available throughout India via the manufacturer, supplier, or authorized traders. Customized assistance ensures correct setup, optimal performance, and long-term reliability.Q: What is the general process involved in operating this ring frame machine?

A: Operators load fiber rovings onto the machine, set the desired spindle speed and draft ranges, and rely on the automated system for yarn spinning. The centralized lubrication and control panels streamline daily operation and maintenance.Q: What are the main benefits of using a low-noise, robust ring frame in a spinning mill?

A: Low noise levels create a better working environment, while the robust frame minimizes vibrations and ensures consistent yarn quality. Additionally, energy efficiency and high spindle capacity result in lower operational costs and higher production rates.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Textile Spinning Machinery Category

High Speed Roving Frame Machine

Price 1 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : 3500 kg

Capacity : 120 Spindles/Set

Frequency : 50 Hz

Dimension (L*W*H) : 8000 x 1200 x 1800 mm

Send Inquiry

Send Inquiry