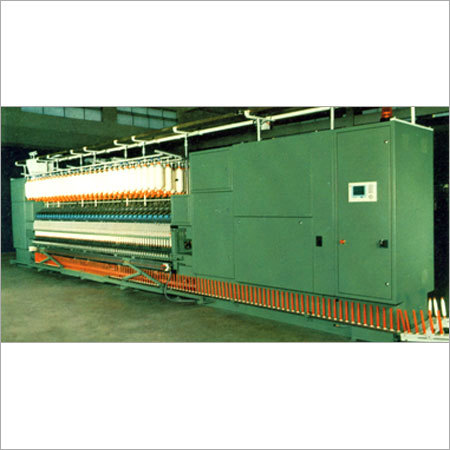

High Speed Roving Frame Machine

Price 1 INR/ Unit

High Speed Roving Frame Machine Specification

- Frequency

- 50 Hz

- Hook

- Automatic

- Product Type

- High Speed Roving Frame Machine

- Material

- Mild Steel

- Machinery Type

- Spinning & Textile Machinery

- Capacity

- 120 Spindles/Set

- Voltage

- 380V

- Power

- 7.5 kW

- Dimension (L*W*H)

- 8000 x 1200 x 1800 mm

- Weight

- 3500 kg

- Color

- Blue and White

High Speed Roving Frame Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 1 Week

About High Speed Roving Frame Machine

With the assistance of reliable and trusted vendors, we bring forth for our clients technologically upgradedHigh Speed Roving Frame Machine. This roving is widely used for knitting or making yarn from wool fleece, raw cotton and other fibers with high speed. Offered roving is manufactured by vendors deft technocrats using premium quality components and cutting-edge technology. Available in several technical specifications, thisHigh Speed Roving Frame Machineis offered at the most reasonable price to the clients.

Features:

-

High operational fluency

-

Rugged design

-

Easy maintenance

-

Longer service life

Advanced Automation and Control

Equipped with a PLC-controlled system and automatic hook and doffing features, this roving frame machine minimizes manual intervention, leading to greater productivity and smoother operation. Speed adjustment is managed via inverter control, enabling precise spindle speed modulation for various yarn types, while the pneumatic pressure system ensures consistent performance.

Designed for High Performance

With a spindle speed of up to 1400 RPM and a bobbin size of 40 x 300 mm, this machine offers rapid production without compromising yarn quality. The double row creel and 150 mm traverse support continuous operation, and the 3-phase AC motor delivers stable power to handle intensive spinning tasks.

Reliability and Safety Built In

Constructed from sturdy mild steel, the machine is engineered for long-term durability. Operating at noise levels below 85 dB and featuring a blue and white color scheme, it ensures a comfortable and aesthetically pleasing work environment. All components are built to meet strict safety and energy standards for consistent operation.

FAQs of High Speed Roving Frame Machine:

Q: How does the auto doffing feature enhance productivity on this roving frame machine?

A: The auto doffing system automatically removes filled bobbins and replaces them with empty ones, significantly reducing manual labor and downtime. This leads to continuous operation and improved overall productivity in yarn spinning processes.Q: What are the key benefits of the PLC control system in this machine?

A: The PLC (Programmable Logic Controller) enables precise and automated control over machine functions, such as spindle speed, traverse, and doffing sequences. This enhances efficiency, ensures product consistency, and simplifies machine management.Q: When should speed adjustment be made, and how is it controlled?

A: Speed adjustments are made when different yarn qualities or bobbin requirements demand a change in spindle speed. The inverter-controlled system allows operators to easily modify speed settings, ensuring optimal performance for each production run.Q: Where is this high speed roving frame machine best utilized?

A: This machine is ideally suited for textile spinning mills and factories engaged in large-scale yarn production, especially in environments where automation, consistency, and efficiency are essential.Q: What is the process for installing and operating this roving frame machine?

A: Installation involves positioning the machine (8000 x 1200 x 1800 mm) on a suitable factory floor with a 3-phase power supply at 380V and 50 Hz. After setup, operators use the PLC interface to configure machine parameters and start the spinning process, with ongoing monitoring for optimal output.Q: How does the pneumatic pressure system benefit machine usage?

A: The pneumatic pressure system ensures consistent and smooth movement of key components, reducing wear and enhancing long-term reliability. It also supports uniform yarn production through stable, repeatable operation.Q: What makes this machine advantageous compared to conventional spinning equipment?

A: With features like high spindle speed, auto doffing, PLC control, inverter-driven speed management, and low noise operation, this machine delivers faster production rates, improved safety, and reduced operating costs compared to traditional spinning machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Textile Spinning Machinery Category

Ring Frame Machine

Price 1 INR / Unit

Minimum Order Quantity : 1 Unit

Machinery Type : Other, Spinning Machinery

Material : Mild Steel

Product Type : Other, Ring Frame Machine

Color : Blue & White

Send Inquiry

Send Inquiry